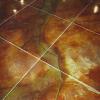

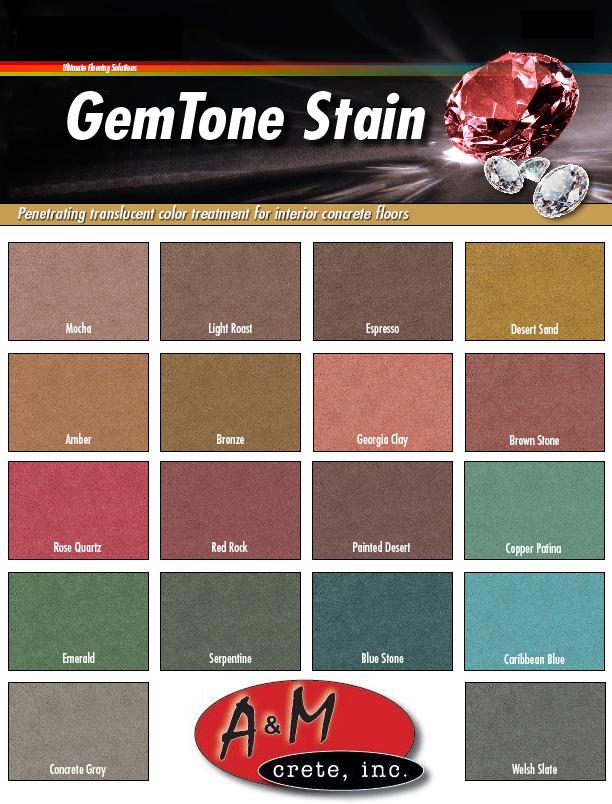

Concrete slabs have an inherent natural beauty, but until recently, residential and retail facilities preferred floor coverings, such as vinyl composite tile, decorative tile or terrazzo, to make up for the perceived lack luster of concrete’s natural state. However, the benefits of natural concrete, such as cost savings and high-traffic durability, have long been a familiar solution for industrial sites.